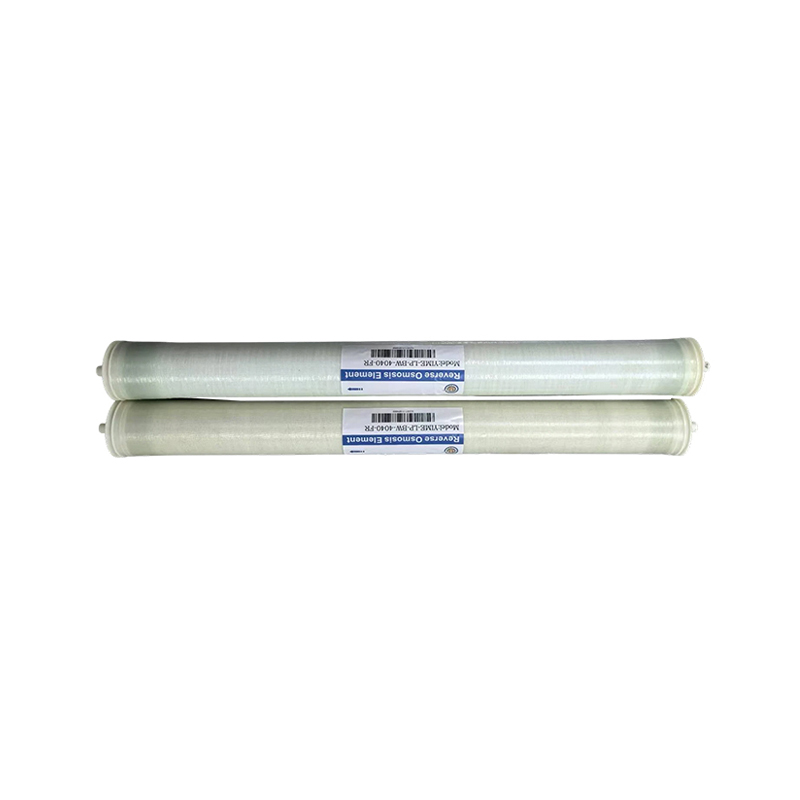

Industrial Reverse Osmosis Membrane ULP-8040

ULP-8040ULP-8040 Industrial Reverse Osmosis Membrane: Water Filtration Solutions(Already modified)

Ro Membrane 8040 is one of the best industrial-grade reverse osmosis membranes for large-scale water treatment systems. It is essential for a variety of processes such as desalination, wastewater recycling, and the production of clean and ultrapure water. For industries such as petrochemical, power, food and beverage, and electronic manufacturing, this high-efficiency membrane guarantees the removal of contaminants such as salt, heavy metals, bacteria, and other impurities.

-

Installation:

Ensure proper alignment of the membrane in the pressure vessel. Make sure the o-rings and seals are correctly positioned to prevent leaks.

Connect the feedwater inlet and permeate and concentrate outlets securely. Follow the manufacturer's guidelines for setting up the pressure and flow rate according to the Industrial RO Membrane ULP-8040s specifications.

Operating Conditions:

1. To achieve optimal filtration, the membrane should operate under a pressure range of 150 to 225 psi. For peak performance and membrane longevity, keep the temperature within 5°C —45°C.

Adjust the water recovery rate based on the feedwater quality. A recovery rate between 40% and 75% is generally recommended, depending on the type of feedwater.

2.Maintenance and Care :

Regular Cleaning: To maintain the efficiency of the Industrial RO Membrane ULP-8040, perform a chemical cleaning every 3-6 months or as needed based on the fouling rate. Use approved cleaning chemicals to remove scale, biofilm, and other contaminants that accumulate on the membrane surface.

3. Storage Guidelines: If the membrane needs to be stored for an extended period, ensure it remains wet. The membrane should be stored in a sealed, airtight container with an appropriate preservative solution to prevent microbial growth. Avoid exposure to direct sunlight or freezing temperatures.

4. Replacement Schedule: Typically, the Industrial RO Membrane ULP-8040 should be replaced every 2 to 3 years, depending on the usage and feedwater quality. High levels of impurities in the feedwater may necessitate more frequent replacements. Keep an eye on the permeate flow rate and desalination efficiency to determine when the membrane performance starts to decline.

If you're unsure about the right time to replace your membrane or need assistance, don't hesitate to contact us. We can help assess your system's needs and provide timely replacements to ensure continued operation. -

Model:ULP-8040

Size 8-inch diameter, 40-inch length

Flow Rate 10,000 GPD (Gallons per Day)

Desalination Rate ≥ 99.5%

Operating Pressure 150-225 psi

Operating Temperature 5°C - 45°C

Our membrane products are ideal for both industrial and municipal applications, ensuring clean and safe water.